How St3ms® Is Turning Banana Plant Waste Into Natural Performance Textiles

St3ms® performance-first yarns are engineered for durability and comfort; with impact as a benefit. | St3ms®

How do you build the next generation of natural performance materials without pretending cotton or synthetics will disappear?

That’s the practical premise behind St3ms®, a materials startup co-founded by Chase Kahmann and Eduardo Gonzalez, turning banana plant pseudostems into durable textiles. Their focus isn’t to wage war on existing fibers. It’s to carve out a lane where sustainability is earned through performance, economics, and scale.

Kahmann and Gonzalez met while working on sustainable innovation in the apparel ecosystem. Their partnership works because their instincts pull in different directions. Kahmann is “the crazy one who sees light at the end of the tunnel,” constantly asking, “Hey, is this possible?” Gonzalez provides the technical grounding. “I have all my technical expertise, and Chase goes where nobody has gone before,” he said.

Together, they’re trying to solve a familiar problem in materials: ideas that look promising in a lab, but never become something a supply chain can actually adopt.

A decision to build beyond the desk

Gonzalez has been in innovation work “35 years and plus,” including leadership in sustainability and material innovation. He and Kahmann didn’t set out to create another prototype with a good narrative. They wanted to build something with a real path to industrial adoption.

“At the time, we were looking for something beyond just the desk,” Gonzalez said. “Ideas that are just sitting in the doors and drawers. We wanted something that really can make the difference in the world.”

Kahmann came up through product design and the apparel and footwear space. Working alongside Gonzalez, he said, “It set my mind on fire,” especially the technical side of how new materials actually come to fruition.

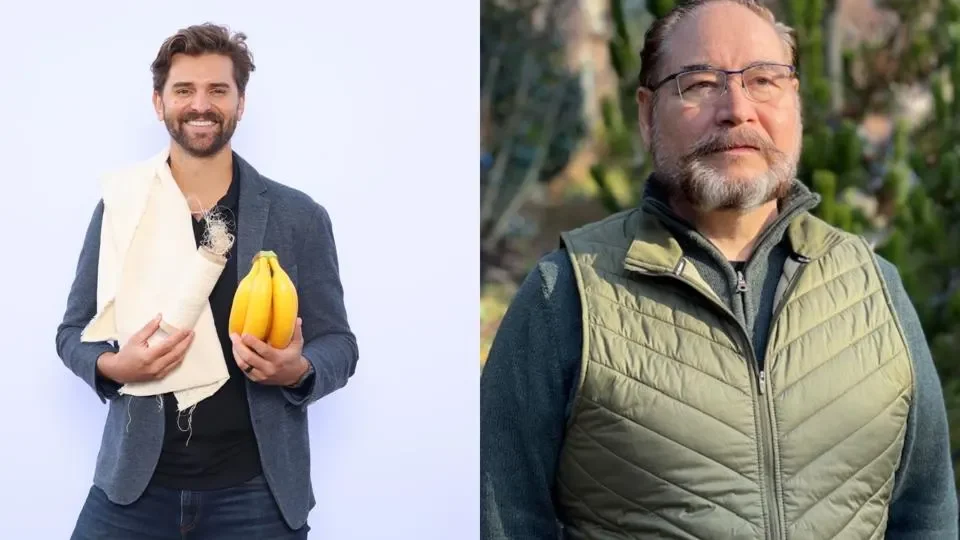

From left to right: Chase Kahmann, CEO and Co-Founder, Eduardo Gonzales, Co-Founder and CTO at St3ms® | St3ms®

Why bananas, and why the pseudostem matters

St3ms® started with banana fiber for textiles for a straightforward reason.

“Initially we started with banana fiber for textile because it was a low-hanging fruit,” Gonzalez said.

The founders see a gap between cotton and synthetics that is both functional and environmental. “Cotton being the fabric that everybody likes is very nice,” Gonzalez said, but it is “very water intensive,” tied to “insecticides, pesticides.” Polyester and other synthetics are versatile and cheap, but he described them as “very carbon intensive.”

Between those poles sits what Gonzalez called “this empty space,” where a new category of materials can compete.

Bananas bring something else that matters if you’re trying to build at scale: a regenerative cycle that produces a steady stream of biomass.

“It’s like a tulip,” Kahmann explained. “You plant the plant once and then it will regrow for 24 years.”

After the banana bunch is harvested, farms cut the pseudostem down to the ground. The root ball stays in place and keeps producing multiple stems over time. For St3ms®, that discarded pseudostem is the feedstock.

But the team is careful not to frame this as “take it all.” Kahmann said they only want “a very specific percentage,” because they want to “optimize biodiversity… the soil and the plant health.”

For St3ms®, bananas are the starting point, not the entire thesis. Gonzalez framed the larger ambition as turning “natural waste resources into a new product.”

“There is a lot of natural waste that can be converted into products,” he said. “This is waste that is just sitting there for somebody to take advantage.”

A process designed for the real world

The biomaterials space is crowded with impressive experiments that never leave the pilot phase. Gonzalez has a name for those: “Curiosities of the lab.”

St3ms® is trying to avoid that trap with a proprietary process built for industrial conditions. Gonzalez said the company has filed four patents and described the process as aligned with “the 12 principles of green chemistry,” emphasizing that it is designed to avoid pollution and difficult discharge management.

But he kept coming back to the same question.

“From our experience, can you scale it? Can it be economical? That’s the biggest thing,” he said.

That practicality shows up in how St3ms® is approaching its first commercial material. Kahmann explained that their early product is a blend. With a “30% banana cotton blend,” they can manage costs and scale without needing massive banana fiber volumes from day one.

St3ms® is trying to avoid that trap with a proprietary process built for industrial conditions | St3ms®

Performance first, hype later

St3ms® is not positioning itself as a novelty fabric. Kahmann said the commercial path is “really leaning into that performance aspect of the material,” targeting categories where durability is non-negotiable.

“Workwear, kids clothes, upholstery,” he said.

He acknowledged those are “slightly the less exciting hype part of the industry,” but he sees them as the fastest route to credibility. “We have to prove that we can do what we say we can do,” he said.

The team’s early results surprised them. Kahmann said the technology “just so happens to create a really strong yarn,” which makes “durable textiles.”

They avoid direct public comparisons, but Kahmann offered the internal benchmark that frames the ambition.

“We think about ourselves as being the Cordura of natural fibers,” he said.

St3ms® was founded on a simple discovery: the stem fibers of banana plants can be transformed into performance materials. | St3ms®

Supply chain first, then scale

A feedstock story only matters if it becomes a supply chain. Kahmann said the company spent “about nine months just networking” in 2022, building relationships and learning the realities of Guatemala.

“If we look at this as a quick, advantageous, ‘let’s sell waste for as much as we can,’ then there is no industry,” he said. “But collectively, we can build something big.”

St3ms® partnered with a single industrial farm to start. Kahmann described them as “incredible partners,” allowing the team “to learn and mature over the years.”

Funding and the proof gap

St3ms® is still in the stage where progress requires capital, and capital requires proof. Kahmann said the company has “raised $1.3 million to date since 2022,” while bootstrapping and pushing resources into scaling the process toward commercialization.

He also described a shift many early-stage climate and materials companies are feeling.

“We’re in a different era where purchase orders are more difficult to come by,” he said, “where you have to show more progress before any PO will be provided.”

In the middle of that push, St3ms® received a meaningful signal of validation from the Inter-American Development Bank, which Kahmann described as “huge” support after an extended diligence process. For him, it reinforced the banana plant’s broader industrial potential.

“It’s beyond fruit,” he said. “It’s kind of like corn, where corn does a ton of stuff for the world. Bananas are right there.”

Not against cotton or synthetics

St3ms® isn’t selling purity. It’s selling a realistic third lane.

“We are not against synthetics. We are not against cotton,” Gonzalez said. “Cotton is never going to go away. The synthetics are never going to go away.”

Instead, he said, “We are just finding our own space.”

And the space they’re aiming for is defined by the same three-part test Gonzalez returns to again and again.

“You need to have sustainability, you need to have performance, and you need to have economics,” he said. “All these three things together, they make something that is going to make a difference.”

At Conspiracy of Love, we help changemakers tell their most powerful stories — stories that inspire action, build movements, and create lasting impact.

Find out more about our Values-Driven Storytelling and GPS to Purpose workshops, and how we can help you scale your impact.